Napredni akrilni lateks tesnilni premaz iz kovine Mit-ivy z odlično prodorno močjo

Uporaba

Ima odličen oprijem na jeklene podlage in podobne temeljne premaze na vodni osnovi ter odlične fizikalne in mehanske lastnosti po sušenju barvnega vala.

5. Barvni film po sušenju odlično ohranja svetlobo in barvo.

Priporočena uporaba Primerna je za zaščito pred odtoki tovornjakov, delov strojev, lahke industrijske opreme itd., Kjer je potrebna visoka zaščita.

Tehnični podatki Raznobarvna barva

Suha površina (50% mešljivost) 15 ℃ C <1h ; 25'C <0,5h

Trdno suho (50% vlage) 15'C <48h; 25 ° C <24 ur

Zadetki "kg.cm" 50

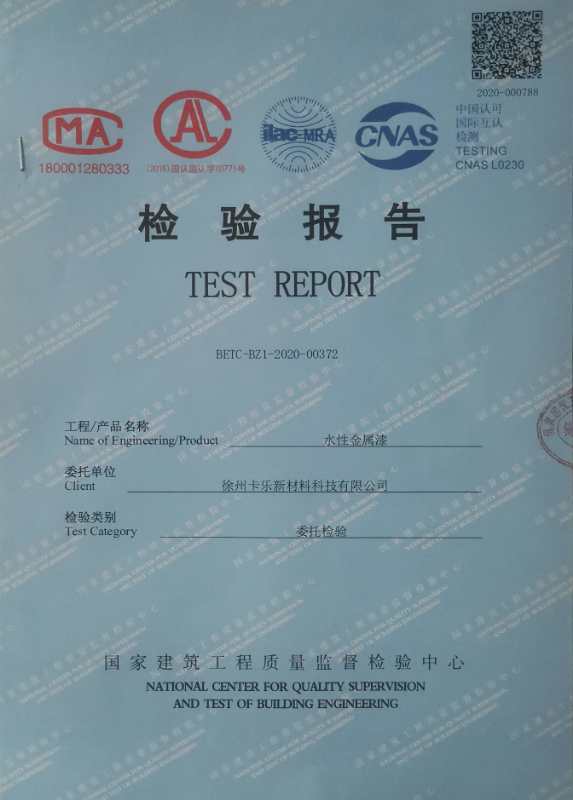

Vodna (50 ± 5μm) 72-urna barvna folija ne mehurja, ne pomaga pri padcu in ne rja.

Trdota 0,3 (dvojno nihalo) mehanske lastnosti debelina filma (23 ± 3jμm)

Adhezija (hegelovska) 1. stopnja

Površinska obdelava Na površini prevlečenega materiala ne sme biti vlage, olja, kislega ogljika in pepela.

Hitre podrobnosti

Jeklo z oksidno kožo: Peskanje ali peskanje, na primer obdelava do nivoja Sa2,5, kjer peskanja ni mogoče opraviti, je treba mehansko polirati ali

Kemično obdelana za odstranjevanje vseh plavajočih zlomljenih ramen.

Jeklo brez oksidne kože: peskano (peskano) do Sa2.5 ali zračno aktivirano električno orodje za brušenje do St3.

Varjenje, rezanje plamena ali ognjemet za požgane površine loka: brušenje do nivoja St3.

Osnovni material s starim barvnim filmom: odstranite ostanke starih delcev barve in rje in z brusilnimi orodji izbrusite St3 do peska.

Tipičen paket za barvanje lahko uporabimo s temeljnim premazom na vodni osnovi H902, lahko ga uporabimo samo kot splošni dekorativni premaz ali z drugimi vrstami temeljnih izdelkov (za preverjanje jih je treba uskladiti).

Construction data Table dry (50% temperature) 15'C<th;25℃C<05h Actual dry (50% humidity) 15℃C<24h;25℃<12h Density about 1.1-1.20g/cm' Theoretical coating rate 0.15-0.2kg/m' (dry film 40-50) μm)

It is recommended to apply 2 coatings, which can be applied in the way of warm touching temperature to ensure that the dry film is 40-50μm.

To be sanded and finished with sandpaper.

Construction method Air or robot spraying is possible. Mix the paint before use, adjust the viscosity according to the construction method.

Add 5-15% of water. Add water and stir evenly, then leave the surface to work without bubbles.

Construction environment 1. The brain playground should have good ventilation and dust removal facilities to ensure the quality of construction.

2. The construction should be carried out under the condition that the mixing degree is above 5℃C and the relative humidity of the environment should be <70%.

3. The substrate temperature shall be not less than 5' and shall be more than 3'C above the air dew point temperature.

washout

| Vehicle Type | 100% Acrylic Latex | |

| COMPOSITION (nominal) | Pigment : Lightfast Non-Lead Pigments & Mineral Extenders.

Blinder : Acrylic Emulsion. Solvent : Water. |

|

| Volume Solids | 31.8% | |

| Coverage per Gallon at Recommended Film Thickness | 400 –450 Sq. Ft. (37-42 m2) | |

| Recommended Film Thickness

(Depending on surface texture and porosity. Be sure to estimate the right amount of paint for the job. This will ensure color uniformity and minimize the disposal of excess paint) |

Dry 1.2 mils

Wet 3.8 mils |

|

| Dry Time @ 77° F (25° C) @ 50% RH

(High humidity and cool temperatures will result in longer dry, recoat and service times.) |

To Touch 1 Hour

To Recoat 2 to 4 Hours |

|

| Dries By | Evaporation, Coalescence | |

| Viscosity | 99 ± 2 KU | |

| Gloss / Sheen | Flat (5-10 @ 85°) |

| Shipping time by Sea (Just for reference) | ||||||||

|

North America |

11~30 days | North Africa | 20~40 days | Europe | 22~45 days | South-east Asia | 7~10 days | |

| South America | 25~35 days | WestAfrica | 30~60 days | MiddleEast | 15~30 days | East Asia | 2~3 days | |

| Middle America | 20~35 days | EestAfrica | 23~30 days | Ocenia | 15~20 days | South Asia | 10~25 days | |

FAQ

1.About Sample

We provide free sample for testing.

2.OEM,ODM service available.

3.According to customer's request, packed with pallet or without pallet.

Tile adhesive(20kg/bag)packing with pallet specification:

64 bags/pallet = 1.28 MT/pallet

72 bags/pallet = 1.44 MT/pallet

One full 20ft container max loading 27.6MT.

With pallets can load 1360 bags, without pallet can load 1380 bags.